.jpg?width=300&name=ROI-Blog-Hero-Part-2(Compressed).jpg)

Utilizing technology to decrease human error

This is part of a series of how to increase ROI.

In this series we go through several areas where companies can increase ROI. Here, we will discuss how human errors can be decreased with the help of technology.

We’re all human, we all make mistakes. But how much time can we justify being spent on fixing these mistakes and are there ways to make sure these mistakes don’t happen in the first place?

It’s a well-known assumption that technology is replacing jobs, but its impact can also be seen as an enriching experience. One where workers can spend their time on more rewarding and valuable tasks, rather than searching for errors.

The problem with relying solely on human abilities

We’ve had multiple customers report that it can be necessary that the same project is redrawn multiple times within the bidding process. On average, companies redraw each project up to seven times. Is this really the most efficient use of their time? And, this average of redraws is before a company has even won the deal to make all the work pay off!

So, why is so much time and resources spent on redrawing the same project?

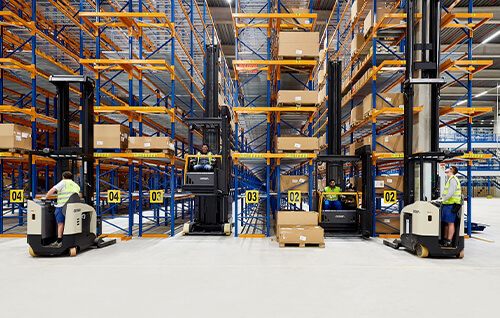

The simple answer is that different departments need different parts of the drawing and each of them is using different tools. It is easy to see that this requires a lot of time, leads to duplicate work, and increases the risk of errors.

With so many redraws, the specification list needs to constantly be updated. If this is done manually it’s very easy to miss changes, forget to add parts, or simply type the wrong part number.

Companies are aware that it is very easy to make mistakes during the design process so what do they do? They put another person on proofing the specification. More time, money and resources wasted in an attempt to decrease human errors.

EXAMPLE:A mockup is created by sales to give an idea of what the customer project might entail. It then goes to the engineers or designers to create an accurate drawing before the same project is redrawn a third time to be specified to calculate the costs. After the project has been specified it is time for installation to take a stab. In this simplified example, we already see four redraws done by different teams. |

But the problems don’t stop there. If a mistake still slips through this manual process, the costs this might incur down the line can be huge.

Just imagine typing the wrong part number and your client’s entire kitchen is delivered in the wrong color.

Or the wrong amount is ordered on a product that already has several weeks of lead time. Worst case, this could halt the entire installation, resulting in potential scheduling conflicts and maybe even require to rearrange other projects in order to accommodate the fix of the first one.

One small error leads to a ripple effect through multiple departments, creating increased costs, delayed deliveries and overall frustration for both customers and employees working on the project .

The SOLUTION

Luckily, there are better processes and tools available to solve these problems. The human competence and interaction with customers are still key to successful sales, but with the right tools and technology the job can be made more efficient, precise, and enjoyable so the focus can be on the human interaction instead of the technical details.

So how is this done?

- With the right technology, several people can work simultaneously in the same drawing – removing the need to redraw - and, with that, automate many steps along the way. By just removing the need to redraw, we remove countless of steps where human errors could result in increased costs and lost profits.

- Another win is that sales can always work with accurate products and pricelists, which means that they can instantly provide a more accurate quote to the customer without having to rely on multiple departments.

- Designers and engineers can continue to work with the drawing from sales, which is already aligned with what the customer wants, saving countless of hours of redrawing and sending revisions between multiple departments.

- Another major win is when everything is automatically specified in the background as it is being drawn and installation drawings can be automatically generated once the drawing is completed.

This is the new way of working and it has already been proven successful. Many of our customers have reported that project times have decreased from months to weeks, or from weeks to hours depending on the industry thanks to these streamlined processes after introducing CET into their organization.

Want to learn more about how to create more efficient processes? Check out these five tips for creating an omnichannel strategy.

SUBSCRIBE FOR MORE CONTENT LIKE THIS

Subscribe to the Configura Blog to get notified whenever we post something new: