RESOURCES

-

ONBOARDING

-

DEVELOPMENT PHILOSOPHY

-

PROJECT MANAGEMENT

When you adopt CET, you change from your usual way of doing business to something far more efficient. By following this roadmap of How to adopt CET, the process will be efficient, enjoyable and, most important, successful!

DOWNLOAD

The Catalogue Creator is a tool for an individual or organization to produce, maintain, and publish product data and simple product logic in CET. Catalogue Creator is used together with CET Developer.

DOWNLOAD

Parametric Graphical Configuration (PGC) – is essential to the feel of CET and how users perceive it. For developers, it is therefore central to “feel the pain” and visualize and understand problems and frustration that users could experience.

DOWNLOAD

This document describes the Configura Project Model with the aim to provide guidelines to all team members, both at Configura as well as in the teams of our customers and partners.

DOWNLOAD

This document provides an overview and description of the methodology Configura recommends for implementing an Extension or Catalogues in CET.

DOWNLOAD

Universities around the United States are incorporating CET classes into their curriculum to better prepare students for the increasing demands on interior design professionals. Our CET Education Program gets you enrolled in a few short steps.

DOWNLOAD

This document provides an overview of information around how to work with Configura as an Extension Owner in the Commercial Interiors Industry. It will help you get started, and quickly find important information.

DOWNLOAD

This document provides an overview of information around how to work with Configura as an Library Owner in the Commercial Interiors Industry. It will help you get started, and quickly find important information.

DOWNLOAD

This document provides an overview of information around how to work with Configura as an Extension Owner in the Material Handling Industry. It will help you get started, and quickly find important information.

DOWNLOAD

This document provides an overview of information around how to work with Configura as a Library Owner in the Material Handling Industry. It will help you get started, and quickly find important information.

DOWNLOAD

This document provides an overview of information around how to get started as a user in the Material Handling Industry. It will help you get started, and quickly find important information.

DOWNLOAD

The most important aspect of a PGC solution is the touch and feel of the application, achieved by programming. There should be a natural flowing ease and a general feeling that the PGC software actively assists in making your every idea come to life quickly and easily.

DOWNLOAD

Learn what PGC is and how it works, and increase your understanding of how modern, high-tech computer technology affects the profitability and efficiency of your company.

DOWNLOAD

By introducing dynamic product structures – ones that are not based on static part numbers – a company can take full advantage of configurable products.

DOWNLOAD

Creating great software is a serious challenge and unfortunately many ambitious software ventures fail because traditional factory or office management principles are transferred over to software production.

DOWNLOAD

A lengthy RFP can hinder innovation while a short RFP can increase the time spent searching for a vendor to meet your needs. As a software provider, our perfect RFP explains the problem at hand and gives vendor’s insight into your company and its goals.

DOWNLOAD

This document gives you an overview over Jira and describes the issue handling workflow.

DOWNLOAD

All Jira projects are initially set up by Configura. Multiple Scrum teams can work on the same project. This document describes how you should set up your boards.

DOWNLOAD

OFS was one of the first to implement Stage on their website, resulting in an enhanced user experience for both internal teams and external dealers.

READ CASE STUDY

After being on the Configura platform for nearly 25 years, Martela decided to migrate to CET in 2018. Martela chose CET because of the rich history between our two companies and because CET could enhance Martela’s entire sales process.

READ CASE STUDY

NARBUTAS partners with Configura to expand global growth by developing a CET Extension, meeting dealers and design firms where they work.

DOWNLOAD RESOURCE

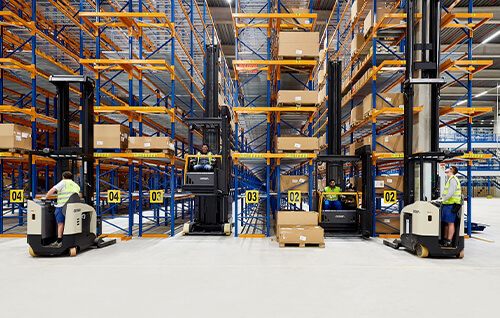

Dematic, a leader in warehouse automation, uses CET and their custom platform Maestro to streamline processes, reducing engineering time by 40% and speeding up estimates by 30%.

READ CASE STUDY

For more than 50 years, NEDCON has led the way in steel storage systems. NEDCON is headquartered Doetinchem, Netherlands with manufacturing in Pardubice, Czech Republic and global branches across Europe and the United States.

READ CASE STUDY

Headquartered in Osaka, Japan, KOKUYO aims to enrich the world through its products including office furniture and stationery. KOKUYO is the first company in Japan to adopt CET, launching its Extension in January 2020.

READ CASE STUDY

With a 40-year history, AJ Products is a prominent player in the Nordic and European markets. Primarily known as a “catalog company” – offering everything from pallet racks to copy paper through its online catalog.

DOWNLOAD RESOURCE

Maars was looking for a tech company with previous experience working with walls because specifying walls quickly can become very complicated. Only a few months after the initial meeting, the project to create Maars’ CET Extension, Maars 4D, took off.

DOWNLOAD RESOURCE

Marbodal – the first customer on the CET platform – is a Swedish kitchen manufacturer whose salespeople have used CET since 2004. Committed to meeting end customers at the right time in the buyer journey, the team at Marbodal decided to invest in a supplementary online drawing tool.

DOWNLOAD RESOURCE

Global furniture company Sunon Group Co., Ltd., headquartered in China, first learned of CET when talking to customers overseas who offered product catalogs via various software solutions. Sunon Group looked into the benefits of CET and officially became a Configura partner in 2016.

READ CASE STUDY

Steelcase has revolutionized the way its dealers sell products. Today, nearly all Steelcase dealers in North America use CET along with the proprietary Extension, SmartTools, as the total solution for their design and specification needs.

DOWNLOAD RESOURCE

Spacesaver was one of Configura’s first customers in the United States. The initial contract was signed in 2001; today, over 300 people around the world use Configura software to specify Spacesaver products.

DOWNLOAD RESOURCE

Midmark’s desire to put rules into place made them especially interested in Configura and the concept of Parametric Graphical Configuration. The ability to build in rules to handle many different configurations and conditions was exactly what the company was looking for.

DOWNLOAD RESOURCE

Troax is a market leader for metal-based mesh protection panel solutions used in machine guarding, warehouse partitioning and property protection.

READ CASE STUDY

Kvik, a manufacturer of Danish-design kitchens, wardrobes and bathrooms, released its CET Extension, Kreator, in 2017. Today, more than 750 Kvik sales and back-office staff use the Extension.

DOWNLOAD RESOURCE

Based out of Lewisburg, Tennessee, Talos manu-facturers components for the parcel packaging industry. In 2019, Talos partnered with Configura to develop a solution that would let its customers design systems faster.

DOWNLOAD RESOURCE

For over 65 years, Kimball International has created design-driven furnishings that have helped customers shape spaces into places with its family of brands: Kimball, National, Kimball Hospitality, David Edward and D’style by Kimball Hospitality.

DOWNLOAD RESOURCE

An early adopter of CET, Tami Shulsen is the design director at Steelcase dealership Midwest Commercial Interiors in Salt Lake City, Utah.

WATCH ON YOUTUBE

Marshall Tate is the CEO at Midwest Commercial Interiors in Salt Lake City, Utah. Since adopting to CET, he’s seen a change in how they engage with clients and how they’ve streamlined internal processes.

WATCH ON YOUTUBE

Proroomz, a small but mighty provider of modern room concepts, has fully embraced CET within their organization. Using the all-in-one software has enabled proroomz to significantly boost efficiency and quality, as well as enhance client interactions and decrease project lead times.

WATCH ON YOUTUBE

Over the years, Steelcase has progressed to handling most software development by themselves. Their largest development team today is located in Kuala Lumpur, Malaysia, where seven developers are working on implementing new features and adding new products.

DOWNLOAD RESOURCE

An early adopter of CET, Tami Shulsen is the design director at Steelcase dealership Midwest Commercial Interiors in Salt Lake City, Utah.

DOWNLOAD RESOURCE

Looking at her CET drawings, you would never guess that Lotta Larson with Lexton Interiör in Norrköping, Sweden, is a self-taught CET user – but she is.

DOWNLOAD RESOURCE

“You can focus entirely on creating a functional and aesthetic kitchen design for your customers. In the same moment as I finish the drawing and design work, the customer’s offer is ready. No post-processing work is necessary.”

DOWNLOAD RESOURCE

”All of my customers have been amazed by the speed with which we’re able to create renderings and revisions with incredible photorealistic quality – they love being able to visualize their space and know exactly what they’re purchasing.”

DOWNLOAD RESOURCE

“I like that I can make global changes with a click in CET and know the results will be accurate. CET lets us be more interactive in our work, and our clients love It.”

DOWNLOAD RESOURCE

“Our efficiency and accuracy rates with CET are much higher (than before we used CET) – not only on the front end of order entry but all the way through installation of product. The software makes designing and specifying a truly rewarding process.”

DOWNLOAD RESOURCE

“Except for general kitchen design knowledge, everything you need to know about products is in the program, and that makes it really easy to learn and use.”

DOWNLOAD RESOURCE

”From a business perspective, it has an unmatched ROI. Our internal processes are far more efficient because of CET. In fact, we’ve cut our production time up to one-half – which lets us do more for our customers.”

DOWNLOAD RESOURCE

“CET is a total tool: used at the very beginning of the sales process when bidding on work, then used in collaboration with the client during the actual design-and-specifying phase, and finally, as part of the ordering of product and the necessary bills of materials and installation documents.”

DOWNLOAD RESOURCE

“We’re seeing fewer bid opportunities come through the door – not because we’re losing projects – in fact, just the opposite – our customers are coming directly to us because they like how CET helps them to visualize their space, calculate costs, validate specifications and give real-time results.”

DOWNLOAD RESOURCE

“I bring my laptop to customer meetings and present with the salesperson. I can directly interact with the customer, working with them to create a space. This collaboration has streamlined the decision-making process. Other software programs don’t have these same capabilities.”

DOWNLOAD RESOURCE

“CET allows our designers to produce quality drawings with precise specifications. The rendering and virtual modeling allow us to help our clients visualize their space so they feel comfortable that what they are about to purchase will meet their employee needs.”

DOWNLOAD RESOURCE

Tara McCrackin teaches CET at Kendall College of Art and Design of Ferris State University (KCAD) to give her students a competitive advantage upon graduation.

WATCH ON YOUTUBE

Kirsten Dalman is a student at Kendall College of Art and Design of Ferris State University (KCAD). She first learned about CET at her internship and saw that learning the program was vital to her success there.

WATCH ON YOUTUBE

Katelyn Boverhof is a student at Kendall College of Art and Design of Ferris State University (KCAD). Using CET has helped her understand Contract Furnishing and opened up her mind to that portion of design.

WATCH ON YOUTUBE

Since 2013, Kendall College of Art and Design of Ferris State University (KCAD) has partnered with Configura to provide its interior design students with a new set of tools that they can use after graduation.

DOWNLOAD RESOURCEWe've gathered and moved our Agreements and Policies.

Find out more about Configura. Who we are, what we stand for and where in the world you can find us Configurans. We also share some more of our history and insight into our suite of products and tools.

DOWNLOAD

During 2024, Configura made strong progress across key industries, launched new products, and improved profitability. The team strengthened customer relationships, expanded the user base, and continued investing for long-term growth.

DOWNLOAD

2023 was a rollercoaster for Configura, marked by economic challenges and cost increases, alongside a strategic pivot in the Commercial Interior industry, next-gen investments, and rapid community growth.

READ OUR 2023 YEARBOOKRead Configura's 2022 Year in Review for comprehensive reports on operations, employee spotlights, industry insights, and a case study.

READ YEAR IN REVIEW

The last year pushed many Configurans and our community to adapt and manage a distributed way of working – and at the same time, we went through the most foundational change we have made since the birth of this company.

DOWNLOAD

大阪に本社を置くコクヨ株式会社は、オフィス家具や文房具などの製品で世界を豊かにすることを目指しています。同社は2020年1月に日本で初めてのCETエクステンションをリリースしました。

資料をダウンロードする

Dematic は、インテリジェントな自動化技 術や物流管理ソリューションの分野で世界を リードする企業です。倉庫運営の効率化や サプライチェーン最適化への革新的な取り組 みで広く知られています。

資料をダウンロードする

OFS は、Carolina やROOM といった系列 ブランドとともに、医療、サービス業、企業 環境など、さまざまな分野に向けたオープン ラインのオフィス家具を製造しています。同社 は、多彩な家具ソリューションを各種ディーラー に提供し、製品全体で高品質かつ革新的 なデザインを実現しています。

資料をダウンロードする

Martela は、北欧におけるトップ3 のオフィ ス家具メーカーの一つとして知られています。 同社は、働く環境や学びの場を利用者目 線で最適化することに特化しています。

資料をダウンロードする

リトアニア発の家具メーカーであるNARBUTASは、米国進出をきっかけに、多くの販売店やデザイン会社が利用しているCETプラットフォームに、自社の家具情報を提供することが、グローバルでビジネスを拡大する鍵だと気づきました。

資料をダウンロードする

NEDCONは50年以上にわたり、スチール製ストレージラックシステム業界をリードしてきました。同社はオランダのドゥーティンヘムに本社を置き、チェコ共和国のパルドゥビツェに製造拠点、ヨーロッパと米国に支社を持つグローバル企業です。

資料をダウンロードする

Troaxは、防護柵、倉庫の間仕切り、資産保護柵に使用される金属ベースのメッシュ保護パネルソリューションのマーケットリーダーです。

資料をダウンロードする

40年の歴史を持つAJ Productsは、北欧およびヨーロッパ市場有数の企業です。パレットラックからコピー用紙までオンラインカタログで提供する「カタログ通販の会社」として知られています。

資料をダウンロードする

Steelcase は同社の販売店が製品を販売する方法を大きく進化させました。現在北米では、Steelcase のほぼすべての販売店がCET Designer に独自のエクステンションであるSmartTools を組み合わせ、デザインと見積もり作成に必要な総合的なソリューションとして活用しています。

資料をダウンロードする

proroomzは小規模ですが、現代的なルームコンセプトを生み出す有能な会社であり、CETの利点を社内で大いに活用しています。1つでさまざまな用途に対応できるソフトウェアの導入で効率と品質を大幅に向上させ、顧客とのコミュニケーションを強化し、プロジェクトのリードタイムを短縮することに成功しました。

資料をダウンロードする